The Wiki for Tale 4 is in read-only mode and is available for archival and reference purposes only. Please visit the current Tale 11 Wiki in the meantime.

If you have any issues with this Wiki, please post in #wiki-editing on Discord or contact Brad in-game.

Guides/Beer

Overview

The national beverage of Egypt. Beer is brewed in a Beer Kettle using various combinations of malt, wheat and honey, stored in a Small Barrel, and served at a Ceremonial Tasting Table.

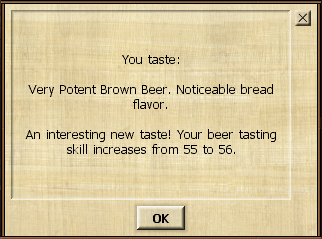

Aside from being drunk to increase Beer Tasting skill (an important route to Perception improvement), beer may be brewed into ambrosia for festivals, or distilled into spirits using an Alembic.

Beer Characteristics

Individual beers can vary across many characteristics, depending on the ingredients and yeasts used in their brewing:

- Potency, or alcohol content: no special potency, Potent, or Very Potent.

- Color: no color, Brown, or Black.

- Sweetness: Dry, Sweet, or neither.

- Special Properties: Fruity and/or Spicy.

- Flavors: up to two of Barley, Bread, Honey, Banana, Blackberry, Cherry, Date, Grapefruit, Orange, Pear, Prune, Jasmine, Vanilla, Cinnamon, Clove, or Nutmeg. Such flavors can be "bold", "noticeable", or merely a "hint".

Beer is stored in small barrels. A barrel of beer is very heavy, with weight 100 and bulk 1. There is no way to empty a full barrel of beer other than by using it (by unkegging it at a tasting table, or by distilling it or making it into ambrosia).

Spoilage

If beer stays too long in the barrel (or on the tasting table), it will eventually spoil, rendering it unfit for drinking. Beer can only go bad after it has been kegged; it can sit in the kettle indefinitely before then. The more potent a beer, the longer it will last after kegging.

- A Very Potent beer will last over a week.

- A Potent beer seems to last one Teppy day.

- A non-potent beer lasts only one Teppy hour.

You will not be told whether a beer has gone bad until you attempt to drink it. Beer will also spoil on the tasting table if left out long enough. Spoilage does not affect a beer's fitness for distilling, ambrosia making, or donating to university research.

Drinking Beer

Beer is drunk at a Ceremonial Tasting Table. Served in mugs, each barrel provides 21 servings. Click on a mug to fill it, then click on it again to drink.

Drinking beer differs from wine in two important respects. First, unlike wine glasses, all mugs are identical -- there is no mug on the table that is "better" for drinking. Grab whatever you like. Mugs are provided automatically and for free; they are not individually crafted as wine glasses are.

Second, the results of a taste of beer are the same for everyone. That is, what you taste is exactly what the barrel has to offer; there is no "beer palate" to refine. (That said, multiple Beer Tasting points can be had from the same barrel -- see the Beer Tasting article for discussion.)

Beer Making Overview

Beer is made from honey or malt (anything else displays "You can only use Malt and Honey in beer."), brewed in a Beer Kettle. You must have the Beer Brewing tech (available at a University of the Human Body) to make beer.

It takes 60 Wood and 25 Water to start a kettle of beer. Once started, the beer making process goes through two phases:

- Brewing (20 minutes) -- in which grain and honey are added to the brew.

- Fermentation (40 minutes) -- in which local microbes enter the kettle and convert the brew's sugars into -- ideally -- alcohol.

The brewing phase counts down from a 1200-second timer. At any point during this stage, you may add grain and/or honey. The type and amount of ingredients, and how early or late in the process they are added, determine a number of factors -- not least the amount of sugar and vitamins available in fermenting.

The fermentation phase counts down from a 2400-second timer. At any point during this stage, you may seal the kettle. Sealing the kettle prevents any (more) microbes from entering. While you can get drinkable beers from an unsealed kettle, most of the time you will want to seal the kettle after the yeast microbe has entered, and before bad microbes enter. (See below, #How to Find and Isolate Yeast.)

Once the fermenting is done, you may leave the beer in the kettle indefinitely. With an empty small barrel in your inventory, you may Take the beer (kegging it). You are given a display showing the statistics of your beer.

- If the beer is undrinkable, it will automatically be thrown out, and your barrel is left empty.

- If it is drinkable, you are given an opportunity to name the beer for later use. (Once you use the beer, your barrel is returned.)

The Details of Beer, or the Brewing Phase

The brewing phase lasts for 1200 seconds, or 20 minutes. At any time during this phase, you may add ingredients (honey and grain) to the kettle. The type and amount of these ingredients will determine some of the attributes of your beer. These attributes are further modified by the time at which the ingredient is added.

- Glucose is a sugar, and is created by grain and honey. Honey adds 10 glucose per unit. Light, medium, and dark roasted malt add 2 glucose per unit. Raw malt adds 1 glucose per unit. Burnt malt adds no glucose. Wheat provides 120% of the glucose of a similarly roasted malt.

- Maltose is a sugar created by grain. Light, medium, and dark roasted malt add 10 maltose per unit. Raw malt adds 5 maltose per unit. Burnt malt adds 2 maltose per unit. Wheat provides half the maltose of a similarly roasted malt.

- Barley flavor is created by malt. The earlier in the brewing phase you add the malt, the stronger the barley flavor. Raw malt gives twice as much barley flavor as light, medium, and dark roasted malt. Burnt malt has no barley flavor at all. The counterpart flavor in wheat beer is Bread.

- Honey flavor is created by honey. It works the opposite of barley flavor: the later in the brewing phase you add the honey, the stronger the honey flavor.

- Color is created by malt. The earlier in the brewing phase you add the malt, the darker the color. Also, the darker the roast of the malt, the darker the color. Burnt malt is mainly used to create color.

- Tannin, a bitter flavor, is created by malt. The earlier in the brewing phase you add the malt, the greater the effect on tannin. Also, the darker the roast of the malt, the less tannin it creates.

- Vitamins, which are consumed by microbes during fermentation, are created by malt and honey. The later in the brewing phase you add the ingredient, the more vitamins are created. The darker the roast of the malt, the fewer vitamins it creates; honey creates fewer vitamins than dark roasted malt, and burnt malt creates no vitamins at all. Raw malt is mainly used for vitamins.

- Grassy flavor is created by raw and light roasted malt. (Grassy flavor can also be created by yeast during fermentation.) The earlier in the brewing phase you add the malt, the greater its effect on grassy flavor. Raw malt adds significantly more grassy flavor than light roasted malt. If grassy flavor goes above 100, your beer will be undrinkable. The counterpart flavor in wheat beer is Herbal.

Note that Banana, Blackberry, Cherry, Date, Grapefruit, Orange, Pear, Prune, Jasmine, Vanilla, Cinnamon, Clove, Nutmeg, and Nasty flavors are determined entirely by the yeast being used. They are not created by the ingredients.

Barley beer is able to produce the following flavors: Barley, Banana, Cherry, Date, Orange, Cinnamon, Nutmeg, Grassy.

Wheat beer is able to produce the following flavors: Blackberry, Grapefruit, Pear, Prune, Jasmine, Vanilla, Clove. They also produce Bread and Herbal flavors, which are the equivalent of Barley and Grassy in barley beer.

Beer Attributes, and the Fermentation Process

*http://www.atitd.org/wiki/tale3/Guides/Beer (Helpful T3 Guide with Base Ingredient Attibutes Chart)

Figuring out what will result in good beer takes three steps:

- finding and isolating a yeast,

- finding out what the yeast does,

- and then using that information to make beer.

Yeast converts sugar into alcohol on a 1:1 basis. Yeast always converts the glucose first, then the maltose. A yeast will always leave a minimum amount of glucose and maltose unconverted; these amounts are called the "glucose floor" and "maltose floor" and are different for each yeast.

In addition, each yeast has a different "alcohol ceiling" -- a maximum # of sugar which it can convert into alcohol.

Example:

- Yeast-17 has a glucose floor of 13, maltose floor of 37, and alcohol ceiling of 992.

- A brewer is using Y-17 to make a beer, using 50 honey and 50 medium malt.

- Total sugars in the brew: 600 glucose, 500 maltose.

- During fermentation, Y-17 will first convert 587 glucose into 587 alcohol (leaving 13 glucose).

- It will then work on the maltose, converting 405 maltose into 405 alcohol (leaving 95 maltose).

- It will then stop because it has now created 992 alcohol (the alcohol ceiling).

Finally, a yeast consumes vitamins as it works. If the vitamin level reaches a certain floor (which, again, varies by yeast), the yeast will stop converting sugar into alcohol, no matter how much sugar it has to work with.

To summarize, each yeast has the following attributes:

- Glucose floor

- The yeast will only convert glucose to alcohol if the glucose remaining is above this level.

- Maltose floor

- The yeast will only convert maltose to alcohol if the maltose remaining is above this level.

- Alcohol ceiling

- The yeast will never produce more than this amount of alcohol.

- Vitamin consumption

- The yeast will consume this many vitamins for each unit of alcohol produced.

- Vitamin floor

- The yeast will only produce alcohol if the vitamins remaining is above this level.

- Flavor production

- The yeast will produce roughly a certain amount of each flavor for each unit of alcohol produced.

A sealed kettle which contains a single yeast may be modeled as follows:

- Start with 10 yeast

- If the vitamins remaining is less than the vitamin floor, stop.

- If the alcohol produced is greater or equal to the alcohol ceiling, stop.

- Consume 1 glucose per yeast, up to the limit set by the glucose floor.

- If the previous step left any yeasts unfed, consume 1 maltose per unfed yeast up to the maltose floor limit.

- Produce 1 alcohol and proportional flavors per sugar consumed.

- Yeasts reproduce (typically 10-40%)

- If any yeasts were left unfed, stop. Otherwise continue from step 2.

In other words, the yeast will produce alcohol until one of three things happens:

- It runs out of sugars

- It runs out of vitamins, or

- It produces as much alcohol as its alcohol ceiling.

Yeasts will always convert glucose in preference to maltose.

For multi-yeast kettles, please see my idea about alcohol ceiling on the discussion page -- Amnhotep

Flavor Production in Fermentation

Some flavors generate entirely during the brewing phase, based on the ingredients added (these include Barley, Bread and Honey flavors, which derive from malt, wheat and honey respectively). Most flavors, however, arise during fermentation -- they are created by the yeast(s) as sugar is converted to alcohol. For these flavors, the type and amount are fixed by the particular yeast(s) being used, how much alcohol is produced, and whether the brew contains malt or wheat.

There are two sets of flavors produced in fermentation: those generated by malt and those generated by wheat. If you have no malt in your brew, none of the malt flavors will appear; similarly for the wheat flavors. (A brew containing both wheat and malt will contain both sets of flavors in proportion.)

Flavors derived from malt:

- Orange (fruity)

- Banana (fruity)

- Cherry (fruity)

- Date (fruity)

- Nutmeg (slightly bitter)

- Cinnamon (slightly bitter)

- Grassy (unpleasant)

- Nasty (unpleasant)

Flavors derived from wheat:

- Grapefruit (fruity)

- Pear (fruity)

- Blackberry (fruity)

- Prune (fruity)

- Jasmine (pleasant)

- Clove (slightly bitter)

- Vanilla (pleasant)

- Herbal (unpleasant)

(Note that Grassy and Herbal flavors are also created in the brewing phase from raw and light-roasted grains. Some yeasts produce additional Grassy and Herbal flavor during fermentation.)

If a brew contains neither malt nor wheat (that is, only contains honey), then none of the malt flavors or wheat flavors will generate. Since honey does not create tannin, there will be no bitter flavors to counteract the sugar; the brew will end up "Cloying Beer" and be undrinkable.

Output

You can collect your finished brew anytime after the end of the fermentation phase. You must be carrying a small barrel to do this. When you keg your brew, you will receive data on its attributes -- you will never know for sure how your brew turned out until you try to keg it. If your brew is undrinkable for some reason, it will automatically be thrown out. If your beer was successful, it will be stored in the barrel and you will have the option to name your beer.

Beer Attributes

When you keg a beer, you will be shown the levels of the various attributes as well as the final flavor. The attributes are:

- Alcohol

- The higher the alcohol value, the more potent the beer.

- Color

- The higher the color value, the darker the beer.

- Mold

- Produced if there was mold among the microbes that worked on your brew. If there is too much mold, you get undrinkable Moldy Beer.

- Vitamins

- Vitamins remaining; no effect on the taste of the beer.

- Glucose

- A sugar; the more sugars, the sweeter the beer.

- Maltose

- A sugar; the more sugars, the sweeter the beer. Not as sweet as glucose.

- Lactose

- A sugar. Despite being displayed, there is no way to get lactose in a beer.

- Citric Acid

- Despite being displayed, there is no way to get citric acid in a beer.

- Lactic Acid

- Produced by lactobacteria; too much will produce undrinkable Sour Beer.

- Acetic Acid

- Produced by acetobacteria; too much will produce undrinkable Vinegar Beer.

- Barley

- A flavor produced by malt.

- Bread

- A flavor produced by wheat.

- Banana

- A fruity flavor produced by yeasts from malt.

- Blackberry

- A fruity flavor produced by yeasts from wheat.

- Cherry

- A fruity flavor produced by yeasts from malt.

- Date

- A fruity flavor produced by yeasts from malt.

- Grapefruit

- A fruity flavor produced by yeasts from wheat.

- Orange

- A fruity flavor produced by yeasts from malt.

- Pear

- A fruity flavor produced by yeasts from wheat.

- Prune

- A fruity flavor produced by yeasts from wheat.

- Honey

- A fruity flavor produced by honey.

- Jasmine

- A pleasant flavor produced by yeasts from wheat.

- Vanilla

- A pleasant flavor produced by yeasts from wheat.

- Nutmeg

- A bitter, spicy flavor produced by yeasts from malt.

- Cinnamon

- A bitter, spicy flavor produced by yeasts from malt.

- Clove

- A bitter, spicy flavor produced by yeasts from wheat.

- Tannin

- A very bitter flavor produced by malt and wheat.

- Herbal

- An unpleasant flavor produced by raw and light wheat.

- Grassy

- An unpleasant flavor, produced by yeasts or by raw or light malt. Too much grassy flavor will produce undrinkable Grassy Beer.

- Herbal

- An unpleasant flavor, produced by yeasts or by raw or light wheat.

- Nasty

- An unpleasant flavor produced by yeasts. Too much nasty flavor will produce undrinkable Nasty Beer.

- Microorganisms

- A list of the microorganisms that entered your brew during the fermentation phase, listed in order of when they entered. You can control the list of microorganisms, to an extent, by choosing when to seal your kettle.

Beer Qualities

A beer may have the following qualities:

| Property name | Condition to be met |

|---|---|

| Very Potent | Alcohol >= 1200 |

| Potent | Alcohol >= 800 |

| (no name) | Alcohol < 800 |

| Dry | (Glucose * 2) + Maltose < 150 |

| Sweet | (Glucose * 2) + Maltose > 300 |

| (no name) | 150 < (Glucose * 2) + Maltose < 300 |

| Black | Color > 500 |

| Brown | Color > 200 |

| (no name) | Color < 200 |

| Fruity | Orange + Banana + Cherry + Date + Honey > 500 |

| Spicy | Cinnamon + Nutmeg > 300 |

| Bold flavor | Flavor > 1000 |

| Noticeable flavor | Flavor > 400 |

| Hint of flavor | Flavor > 200 |

| (no description) | Flavor < 200 |

Each flavor in the beer (cherry, nutmeg, etc.) may be "bold", "noticeable", or just a "hint". A flavor that is very strong can drown out a weaker flavor; if you have 1000 honey flavor and 200 barley flavor, the barley will not appear. A flavor is drowned out if it is less than 50% of the most powerful flavor in the beer.

If two or more other flavors are greater than 50% of the strongest flavor, it will have "muddled flavor", and none of the flavors will apply.

Unsuccessful Brews

Not all brews become drinkable beer. There are many situations which will cause a brew to fail:

- Nonalcoholic Soup (undrinkable)

- Alcohol < 100

- Cloying Beer (undrinkable)

- Glucose + (Maltose/2) > Tannin + Cinnamon + Nutmeg + Lactic

- Bitter Beer (undrinkable)

- (Glucose * 2) + Maltose < Tannin + (Cinnamon + Nutmeg)/5

- Caustic Beer (undrinkable)

- (Glucose * 6) + (Maltose * 3) < Cinnamon + Nutmeg (very high fruity flavours can also produce Caustic Beer)

- Grassy Beer (undrinkable)

- Grassy > 100

- Moldy Beer (undrinkable)

- Mold > 100

- Nasty Beer (undrinkable)

- Nasty > 100

- Sour Beer (undrinkable)

- Not well understood, but may be (Lactic + Acetic) > (Glucose + Maltose)

- Vinegar Beer (undrinkable)

- Acetic > 100

(my first attempt yielded Acetic = 73 and an undrinkable Vinegar Beer: Temm) (my first attempt yielded Acetic = 62 and an undrinkable Vinegar Beer; Fugue) (ditto, Acetic=62, Vinegar Beer --Numaris)

- Vinegar Soup (undrinkable)

- Rare, might be Alcohol < 100 and Acetic > Alcohol

The exact effect of Lactic is still uncertain, but I have had several beers that should have been Cloying, but were drinkable, and had some lactic acid. Simply adding lactic to tannin in that formula fits all my results.

Multiple Yeast Beers

Beers can have as many microbes in them as you care to let get in. Mold, Acetobacterium, and Lactobacillus may be hard to work around, because they add factors both harmful and little-studied.

Generally, you see the largest effects on the resulting beer from the first few yeasts in the kettle. While computing each yeast independently may get you a rough approximation of the flavors and alcohol resulting, the results are not really cumulative or averaged.

Vigorous yeasts (with high alco max or low floor values) can have a big effect even if they enter late. One example from the last Telling was of a particular yeast added at the very end of the list of microbes. Its presence or absence made a 300 alcohol difference in the maximum alcohol generated.

Another example:

- I tested two spots:

- 1) Y3 Y59 A6 M63 Y24 M87 L61 Y65 A62 Y49 L44 M47 Y67 L52 Y64 Y90 Y2 M71 M55 Y82

- 2) Y3 Y59 A6 L61 L52 M63 Y24 M71 L44 M47 Y65 Y67 Y90 Y49 M31 L85 Y64 M87 L69 Y91 A22 A62 Y2

- 1 gave 1421 alc and 20 cinnamon, 2 gave 1250 alc and 379 cinnamon. In 1 nearly all of the effect was done by Y3 but in 2 Y59 was able to act more, perhaps something to do with entry times?

More research in this field needs to be done.

- I have had great success with predicting multi yeast recipes. Stats seem to be location/seal time dependent. Exact seal times are important. Just run your yeast tests using teh exact seal time and this will give stats that can be plugged into beercalc to predict recipes. This strategy has worked very well for me for several locations.

Practical Beer Making

How to Find and Isolate a Yeast

There are 100 microbes in the game, of which 58 are useful yeasts. The remaining 42 are useless Lactobacilii, Molds, and Acetobacteria. Microbes that aren't yeasts will make beer undrinkable if they are high enough on the microbe list. Thus, it is necessary in many spots, and useful in others, to isolate a yeast before you try to make beer.

- Yeast

- A desirable microbe which converts sugars to alcohol and flavors.

- Mold

- An undesirable microbe which converts sugars to mold.

- Acetobacterium

- An undesirable microbe which converts sugars to acetic acid (vinegar).

- Lactobacillus

- An undesirable microbe which converts sugars to lactic acid. Very useful if you're making sauerkraut; not so much with beer.

Very little detailed study has been done on molds, acetobacteria, and lactobacteria. These microbes all produce undesirable flavors that will ruin the beer if too strong. It is never desirable to have anything except yeasts in your kettle. In the fermentation phase, your job is to seal your kettle at the proper time to keep out the "bad" microbes and allow only the yeasts.

You isolate a yeast by running a Yeast Test. This kettle option is a shortcut that eliminates the brewing phase, thus taking only 40 minutes to complete. At the end of the test, you take the 'beer' (you need your small barrel!) and get a display of the results. At the bottom is a list of the microbes that are in the kettle, in the order they entered (first to last).

- Run a yeast test (The Yeast option, which takes 25 water, 60 wood, 2400 Teppy seconds (about 44.25 minutes real time)), leaving the lid open until the end. If the first microbe in the list is not a yeast, start over in another spot. Don't forget to have a small barrel with you so you can get the results of the yeast test!

- Once you find somewhere where at least the first microbe is a yeast, run a new yeast test, closing the lid at 1200 seconds (the halfway point of the fermentation phase).

- If the results show no microbes, it means you have closed the lid too soon; run a new test and close the lid at 600 seconds (remaining). If the results show more than one microbe, run another yeast test and close the lid at 1800 seconds to see if you have isolated the time when the first yeast enters the kettle.

- Keep running yeast tests, dividing the times when the yeast might have entered in half, until you get only the first yeast. This tells you your sealing time when making beer -- close the lid at the same time as you did in this successful test so that only this first yeast will be active in your beer.

NOTE: If you are in a spot where the second (or more) microbes are also yeasts, you may also want to try making multi-yeast beer by finding the seal time that gets you only 2 yeasts (or 3, etc, up to however many you have). While the results of multiple-yeast brews are hard to predict, some people have successfully used the beerCalc tool to do this. Moreover, many beers made without sealing the lid are effectively multi-yeast beers, and you can find many such recipes and locations on the Wiki (do a search for your yeast -- e.g., search for Y3 to find pages with recipes for that yeast).

#Yeast Map - please report the locations of the microbes you find in the map above!

Microbe Transition Lines

Hellinar - Inspired by Jaby's work on large scale microbe distribution, I've been testing the changes in microbe distribution on small scales. These tests demonstrate that the microbe population shifts as your kettle crosses coordinate lines. The degree of shift is dependent on the degree to which the coordinate is divisible by two. Thus if the coordinate you cross is divisible by 128, most of the upper microbes will change. On the other hand if the coordinate can only be divided by 8, or 4 or 2, the shift in order is likely to be small. This shift occurs very sharply within a small fraction of a coordinate. So avoid placing kettles on such a high power of two coordinate. On the other hand, if you are searching for new microbes, place four kettles on odd numbered coordinates around the point where two lines divisible by 128 cross. This will give you four sets of well shuffled microbes.

How to Find Out What a Yeast Does, or the Fermentation Phase

Once you have isolated a yeast, if it has not already been analyzed, run a couple of test beers.

Making beer is just like doing a yeast test, except that a brewing period, 1200 Teppy seconds long, is added BEFORE the fermentation period. During brewing, you can add honey and the various malts at any time, though it calculates results in 12-second "ticks." Once you've finished brewing, it immediately goes into fermentation, and you should close the lid at a time that will catch the yeast(s) you want but no other microbes.

You should try:

- One test with low amounts of sugars and vitamins, which should get you at least one of the floor values for your yeast.

- One test with lots of sugars and vitamins, which should get you the max alcohol for your yeast and reveal any flavors it produces.

Don't expect these beers to be drinkable! These are just to get the yeast values which will allow you to make good beers.

Yeast and Recipe Research

Yeast Map

Map is not that helpful, more yeast locations at Yeast Test Day Event and Yerbouti User page

Yeast Attributes

See Yeast Test page to read or post yeast attribute results. These are the numbers you want to plug into the Spreadsheet below.

Recipes

File:BeerCalc T3 1.4.zip (Note this version has a broken cell calculation under Herbal Label (P2). I found a spreadsheet called 1.4.1 from http://www.atitd.org/wiki/tale3/Guides/Beer/Spreadsheet which seems to have more yeast values (probably outdated) but no broken cells) - Cegaiel

File:BeerCalc T4 1 0.zip Please add more yeast values if you want to.

Warning

This information provided courtesy of the Tale 3 wiki, and was converted by cory0210.

Some information might have changed.